About Us

We supply CUSTOM THERMOFORMED PACKAGING based on your needs and will exceed your expectation every time.

We design and manufacture Thermoformed Packaging such as Plastic Trays for Material Handling, Packaging Blister, Clear Clamshell Containers, PETG Trays for Medical Devices, Plastic Shipping Trays, Food Packing Containers, PCB Storage Trays and any similar Custom Plastic Packaging Solutions in India.

Set up by a team of Mechanical, Polymer and Packaging design engineers with more than three decades of experience in Designing, Prototyping, Validating and Mass Production of Rigid Plastic Packaging using Thermoforming technique.

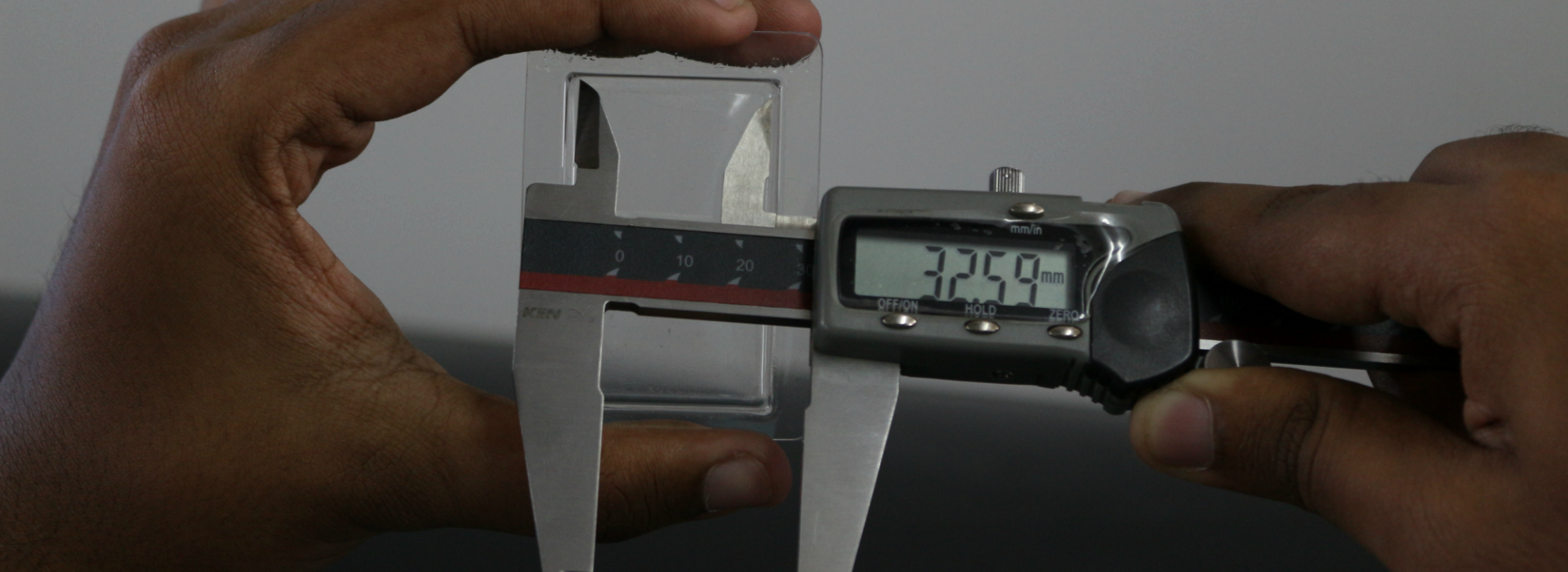

Thermoforming offers low tool cost and short project execution time when compared with other methods of plastic molding such s Injection Molding. Our in house designing and mold making capability offers customers to test the concept packaging within matter of five days.

Manufacturing of packaging is done using automated production line with integrated forming and trimming of parts. We are able to comply with the stringent GMP requirements of our customers from food and medical device industry.